Maintaining an equipment past the end of its service life is a real pain in the neck for Filipino Maintenance Engineers. End of support from the manufacturer and the presence of proprietary hardware and software makes it even worse.

The end of life support from the manufacturer is a good indication that there will be no more available spare parts for the equipment. Sourcing for replacement parts, particularly for third world countries like the Philippines, is next to impossibility. These issues makes the life of a Filipino Engineer like hell. The presence of proprietary hardware and software means that the owner will be at the mercy of the manufacturer for any upgrade that need to be done to cope up with the current technology. It will either be an upgrade of the old technology or a total replacement of the equipment. The later will not be an option due to cost constraints.

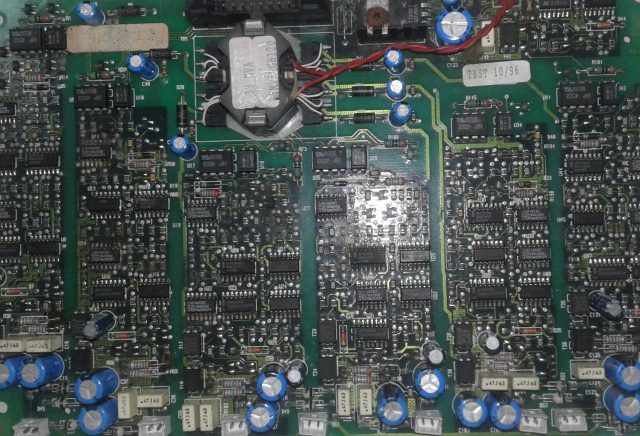

What will be the solution to this maintenance issue? In short term, the electronic cards are being repaired. In long term, reverse engineering is an alternative avenue which has been looked at. One card has already been reversed engineered successfully. However, these solutions has their own pros and cons. Repairing electronic cards means that it is dependent on the availability of electronic components. Repeatedly repaired cards will soon have burnt copper strips which means the end of that particular electronic card reducing further the number of spares. Reverse engineering seems a good alternative. Electronic cards become good as new, however, it will still be an old technology.

The equipment need to be maintained regardless of the solution.