The service life of electric motors is dependent on two (2) main components:

- Electrical components (i.e. windings & insulations);

- Mechanical components (i.e. core, shaft, bearings, frame and cooling system).

The most common causes of electric motor failures are:

- Motor overloading;

- Frequent starting;

- Single phasing or unbalanced power supply;

- Stalling;

- High ambient temperature;

- Loss of cooling.

From the above list, high current is the common denominator except for the two (2) items which are attributed to high motor temperature leading to failure of insulation thus a burnt motor.

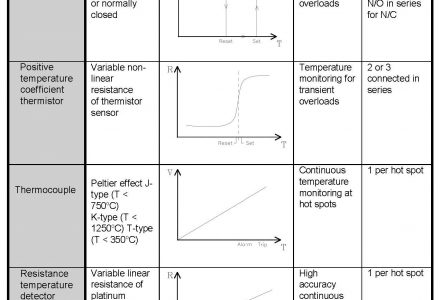

To protect electric motors from thermal overload, direct temperature sensing of the winding temperature is preferable. There are several types of devices that can be used for direct temperature sensing. Some of the most common techniques are:

- Thermostat

- A thermostat is a temperature dependent device that uses a bimetallic strip to change the position of a pair of contacts at the preset rated response temperature. When the temperature exceeds a preset level, the contacts are used to switch an external control device, such as a relay or contactor. To avoid ‘hunting’, some sort of hysteresis is usually built into the device to ensure that the set and reset take place at different temperatures.

Thermostats are usually used in groups of two, with one group having a rated reference temperature of 5OC or 10OC lower than the other to provide a temperature alarm. The second group is used to trip the motor to prevent damage to the winding insulation.

- Thermistor sensors and thermistor protection relays

- A thermistor is a non-linear resistance sensor embedded within the insulation of a motor winding to provide a close thermal association with the winding. It is made from a metal oxide or semiconductor material. The relationship between resistance and temperature is non-linear and the resistance varies strongly with small temperature changes around the set point.

- Thermocouple

- Thermocouples consist of two (2) dissimilar metals joined at one end to form a junction. At the other open end produce a small magnitude voltage dependent on the temperature at the junction. As the temperature changes, the developed thermionic voltage changes to give an indication of the temperature.

- Resistance temperature detector (RTD)

- Resistance temperature detectors (RTDs) monitor temperature by measuring the change of resistance of an accurately calibrated resistive sensor, usually made of copper, platinum or nickel. Tungsten is sometimes used for high temperature applications. RTD sensors can be of the wire wound type, which have a high stability over a period of time, or can be of the metal film types, which are lower cost with faster response but their characteristics can deteriorate over a period of time.

Below table provides a summary of direct temperature sensing motor protection:

Source:

Practical Variable Speed Drives and Power Electronics – Malcolm Barnes